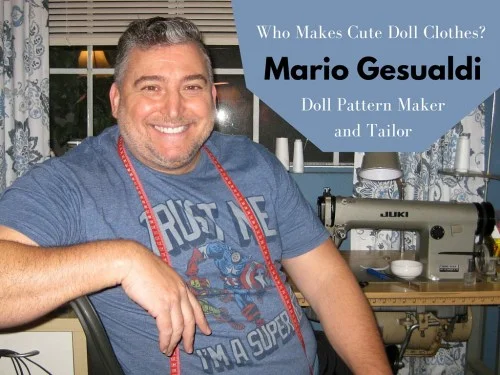

Every doll you find on the shelf at Target starts as a single prototype. Many doll professionals work on creating the dolls that we all love, from Barbie to Bratz. Have you ever wondered who makes those tiny doll clothes? Mario Gesualdi is one of a handful of people in the toy industry who creates doll clothing patterns and sews these tiny garments. Not only does he create doll clothes for clients in the toy industry he also sells reproduction vintage doll patterns through his company Tailored Doll Patterns. I’ve worked with Mario for years and thought it would be fun, and informative, to interview him and find out more about what it’s like to create these miniature garments.

You’ve done a lot of work developing dolls for production and working with manufacturers. Tell me about this part of your job.

Getting your doll on a shelf in a store is the biggest challenge. The fun part is sketching out your design, shopping for fabric, creating a hairstyle and seeing your 3-D sample come to life. Now the challenge begins by putting the doll in the box. Reality sets in and all of a sudden the dreaded “B” word shows up; Budget! Sadly in this industry perceived value determines price point. A doll that retails for $19.99 needs to be in a box that is at least 8″ wide! Consumers associate the size of the package with value. I have always disagreed with this mentality because I throw the box away and what is inside is what matters to me (also my philosophy in life). Knowing that this is a battle that we will never win we start by working backwards. Assume the retailer makes close to a 70% profit and the manufacture shoots for 50-65%, less the material costs of your packaging, overhead for shipping, employees and developments you may have a budget of $3.00 to dress that doll from head to toe. This is where I am expected to turn a sows ear into a silk purse.

“Assume the retailer makes close to a 70% profit and the manufacture shoots for 50-65%, less the material costs of your packaging, overhead for shipping, employees and developments you may have a budget of $3.00 to dress that doll from head to toe. This is where I am expected to turn a sows ear into a silk purse.”

So much is involved in manufacturing a doll. You need a sculptor to help you develop the body, then an engineer to translate into a program that cuts steel to make tooling molds for it. The Engineer will also help to with all you plastic parts and accessories such as shoes, purses and maybe pets.

You need a person for sourcing production fabrics that meets child safety laws globally.

Then there are production pattern-makers, sample-makers, people on an assembly line. Your fashions need to be cheap but still maintain its original aesthetic.

Dolls bodies are made from three different types of plastic materials, ABS, PVC and Poly-Pro. Mixing color for skin-tone is an art form in itself. The formula to achieve that perfect tan will be different for each material because of its chemical properties, shrinkage and cooling rate. It could take weeks to get all the parts to match perfectly.

Next the doll faces are painted. They started with “tampo” printing and then spray masks are made for each color and layer for the doll. Eye shadow has to go on first before the lashes, some doll faces have up to 15 different mask layers. Ever layer is considered an operation and I get billed per operation.

Now its time to root the doll’s hair. Hair style is costed by gram weight and steps, then styling and heat setting. The doll’s head is actually adhered to the insert first. The body is assembled, dressed then plugged into the head and secured onto the insert last before it in inserted into the package. Let’s not forget the packaging design team either. Their design work is done prior to the production process.

“My goal is to give you a gorgeous doll without functional issues, in budget and on time”

We are not done yet, dolls need to go to an outside lab for child safety and heavy metals testing. There are also internal tests that occur such as age and humidity, stress tests to the doll, shipping and drop testing to ensure no damage comes to the doll.

Your manufacturer will continuously send samples to you along the way for approval of each step. Some concerns are minimal but occasionally it is necessary to make on-site approvals because of the challenge of that step or time is an issue to meet schedule. These are just some of the responsibilities I take on as a Production Manager. My goal is to give you a gorgeous doll without functional issues, in budget and on time.

“I loved Mattel because it was my first job in the toy industry and I worked with some amazing people and learned from the best.”

You’ve worked on lots and lots of dolls. Which projects were your favorite? Why?

You might as well ask who is your favorite child. After 19 years in this business working on high-profile brands such as Barbie, Cabbage Patch Kids, Hello Kitty, Olivia the Pig, Taylor Swift, Disney’s Fairies, Princesses, Kim Possible, Jo-Jo’s Circus and licensed products like Samurai Jack, Scooby Do and The Power Puff Girls how do you choose?

If I have to pick the best experience it would be a toss-up between Mattel and a start up company called Possibility Place where I worked on AvaStars.

I loved Mattel because it was my first job in the toy industry and I worked with some amazing people and learned from the best.

AvaStars is a fashion doll with your face printing in 3-D on it. It is an amazing concept which is the ultimate personalized doll. Because it was a startup I got to roll my sleeves up, dig in and was part of the birth of something I felt was special!

Did you play with dolls as a kid? Do the things that you loved as a kid still inspire you?

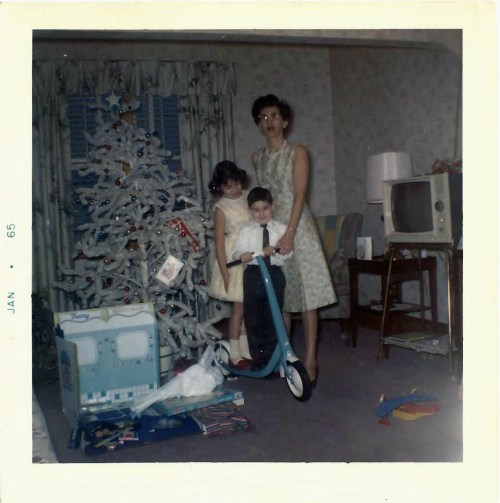

Yes, I did. I have an older sister by three years who decided what and how we played when I was a child. I also loved to color and paint by numbers. My mother was a good sewer back in the day and she would give me her fabric scraps and I would try to make doll clothes for my sister’s dolls, unsuccessfully at that time.

What did you want to do when you grew up?

I was born in Providence Rhode Island and grew up in the town of Lincoln. As a child I usually wore a tie to school even though not required even in high school. I never succumbed to pier pressure and march to the beat of my own drum.

I was not the best of students with the written word; I was a visual learner. I believe that contributed to my eye for details and my sharp memory. My interests were always in Art and Design. I loved going shopping with my mom and was always moving furniture around much to my mother’s dismay.

I attended Rhode Island School of Design and graduated with a degree in Apparel Design in 1985. I worked in the garment industry in New York, Los Angeles and Boston. I eventually fell into teaching design on a college level which was extremely rewarding for me emotionally. It appealed to my nurturing side and helping students achieve their goals and dreams made me very happy.

In 1996 I was recruited by Mattel where I working in development for the Barbie brand for almost six years. I am still in the toy business but would be open to life’s next big adventure if it comes my way.

How did you get started in sewing and creating patterns for doll clothes?

I have always been a pattern maker. It’s just one of the skills I learned in school. It wasn’t until 2005 that I started making patterns for dolls, prior to that there was staff for that wherever I worked. I started making patterns for Cabbage Patch Dolls. Their bodies were a challenge, they have no shape with stretched out arms. I described it as a pin cushion with limbs!

Tell me about your doll pattern business. How did it start?

In 2012 I started to make patterns for Barbie. A friend of mine who was an avid Barbie Collector was going to the Barbie National Convention. He also liked to design his own dolls but was not trained in that field. He asked me to make a few patterns for his designs and then invited me to the convention. It spawned the idea of trying to sell my services to that community, but how? I realized that there is a finite number of original vintage Barbie fashions out there and not everyone can afford to pay collector prices. I decided to knock them off for the home sewer. I started with a baker’s dozen of day dresses and popular fashions. I sold 117 patterns in three days! Since then I have completed a new collection each year and created a website. You can find me at TailoredDollPatterns.com. I have customers in Australia, Italy, the Netherlands and Finland! I have also been interview by the Australian Barbie Club.

How do you promote your business?

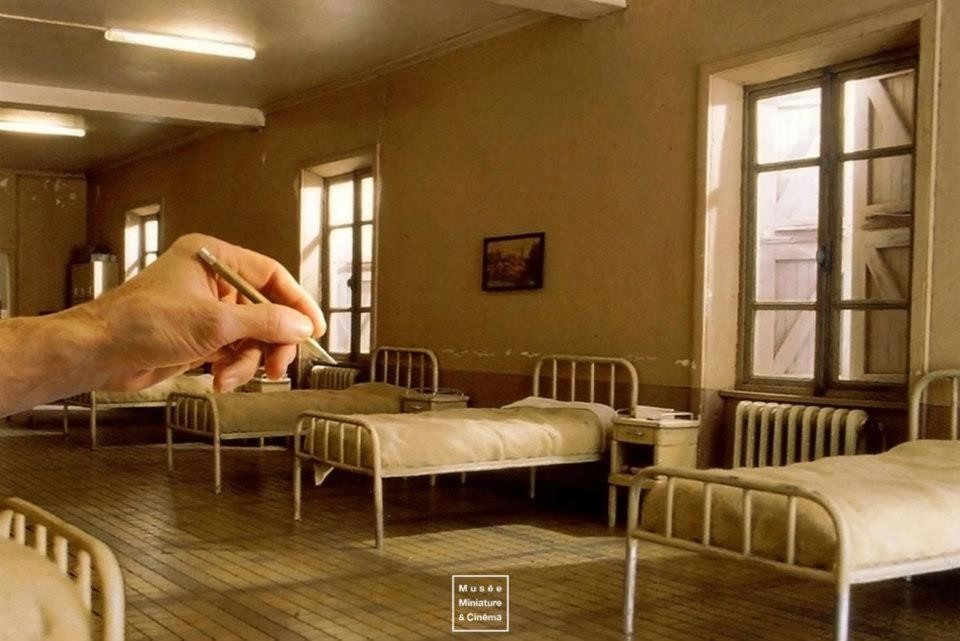

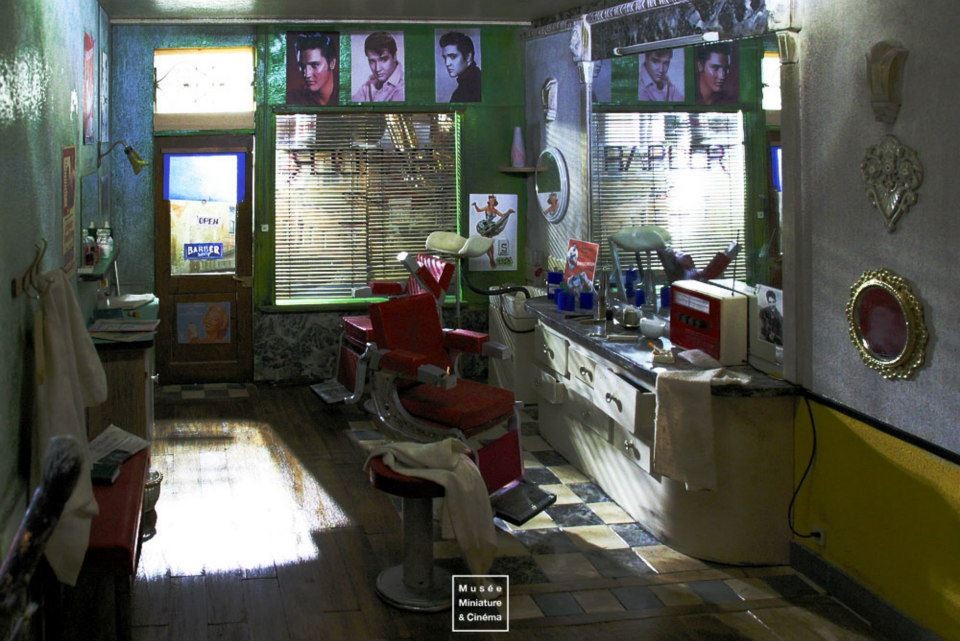

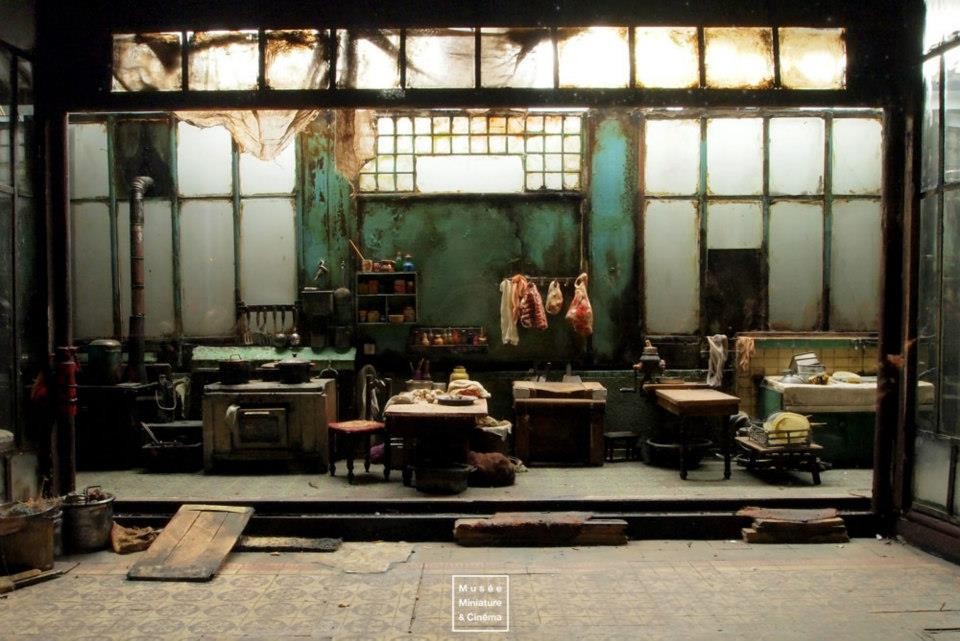

Here is where I need to have my wrist slapped. I am very bad at self promoting. I am fine with attention being brought to my work but a bit shy when it is directed towards me. The toy industry is small and we all know and promote each other so you really don’t need to advertise if your work is good. For my Tailored Doll Patterns business I finally succumb to peer pressure and started a Facebook page. I tried promoting and boosting my posts there. I photo bomb images of my dolls in environments with a cute pun attached to the name of the Fashion and post them.

This year after urging from Heather and mocking of friends at a Christmas party I signed up on Instagram. I’m open to any other suggestions!

Heather Fonseca is a freelance designer specializing in doll design and illustration. Check out her site to learn more about her services and read her blog.